Precision Bending Technology

EVERY BEND MATTERS TO US

With our dedication to customer service and satisfaction, we consistently deliver. We understand partnering with our customer is the key component in everything we do. It is how we deliver the right solutions and execute superior tube bending.

Services

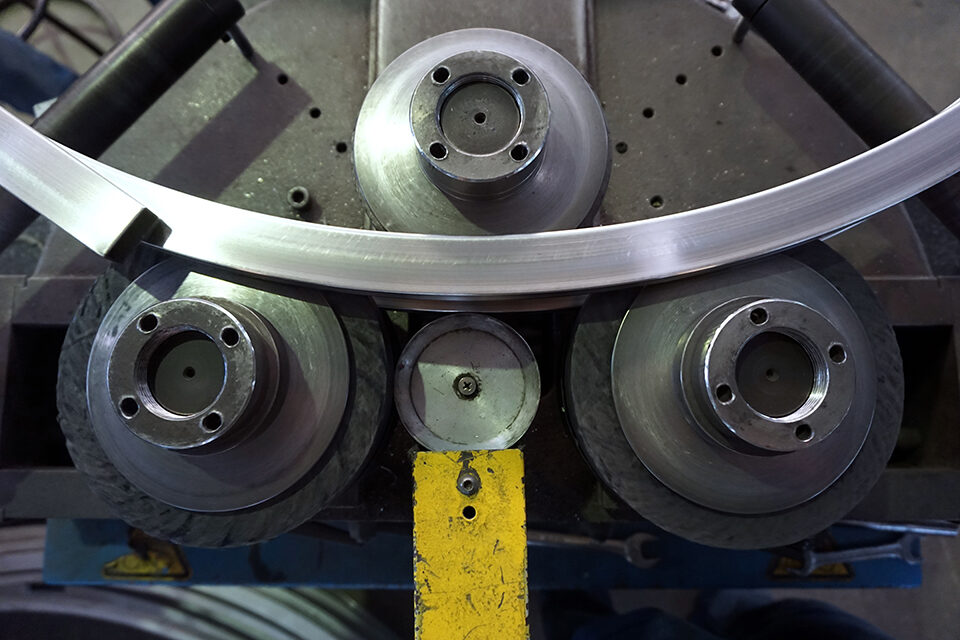

We offer fabrication services for tubing and pipe. Precision Bending has experience in automotive, appliance, plumbing, and other industrial requirements. As a tubular specialist, we offer bending, compound bending, bend-on-bend, flaring and expanding services.

Our in-house precision tube bending includes the capability to create fixtures, tools and gauges that produce and check the critical attributes of your part. Our proven process ensures any tubular part fits and performs as designed.

We support a variety of specialty operations. Many parts need to integrate stampings, machined parts and castings. We manufacture parts with adapters or fittings needing welding or brazing, and we pressure test the entire assembly.

ENGINEERING AND

DESIGN CONSULTATION

We have unmatched custom bent tubing knowledge and provide world-class tube bending. We work with clients to engineer and design complex parts to work for your project while maintaining sound structural integrity.

Although we manufacture complex parts, we make working with our team easy. Get details about our process for partnering with customers on tube bending projects including specification, design, material selection and tube bending costs.

Bending Projects

Consistent and dependable manufacturing quality control is why customers rely on Precision Bending Technology. See our projects that demonstrate our ability to execute complex parts.

Component parts for construction equipment often require complex curved steel bending. We consulted with OEMs to find the optimal solution to their needs with the capacity to deliver large volumes of parts.

We worked with a national appliance manufacturer to create multiple tubing bends with up to 6 elbows. This bent pipe was used as a substitute for costly and time-consuming welds.

Tube components for auto applications are often well concealed but critical to operation. We understand the importance of accuracy and on-time delivery. See our bending project from a recent automotive exhaust tube project.

Process and Equipment

During over 40 years in business, we have acquired extensive equipment and dies that allow us to do a wide range of tube bending processes. We use a variety of bending processes working with materials from carbon steel to titanium and offering sizes ranging from 1” to 6” in diameter.

Need help with a project?

Our team of experts can help with engineered solutions.